The mounting pressure of roller bearings shall be directly applied to the end face of the bearing sleeve with overfilling fit when installing or disassembling the bearing with pressuring method. It is absolutely not allowed to transfer pressure through the rolling body, otherwise it will cause the surface damage of bearing raceway, leading to premature bearing failure. If the bearing is removed and will continue to be used, it is also not allowed to transfer pressure through the rolling body. The mechanism should be designed to facilitate the removal of bearings, and special tools should be used to operate the disassembly.

Needle bearing installed heating method, remove the use of heating or cooling method, the suitable temperature range is 80 ~ 100 ℃, the highest should not exceed 120 ℃. Common heating methods include oil bath heating and induction heating.

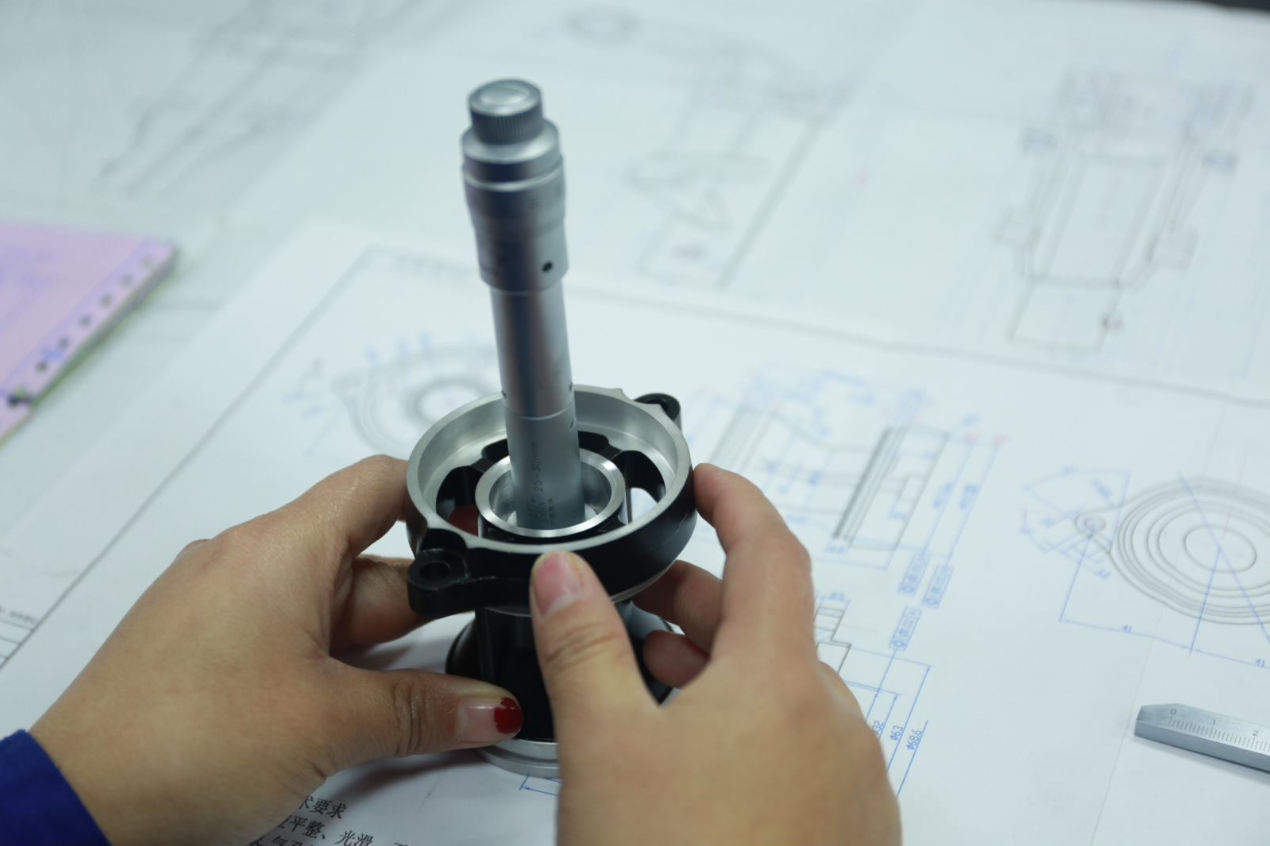

Cone bearing installation, remove the cone bearing is always installed in interference fit, interference quantity depends on bearing on the conical journal or conical set into the distance on the set of length, bearing radial clearance in the process of push, and push the amount decided to cooperate degree, the size of the installation can continuously measure the radial clearance, until meet the requirements of the radial clearance and ideal press fit.